Tight temperature control for superior chick quality

Tight temperature control for superior chick quality

Tight temperature control for superior chick quality

The ventilation system relies on a motor running a fan or paddles continuously during the entire 21 days of the incubation cycle, 24/7

Incubator heating during the first 9 days of the incubation cycle (endothermic eggs)

Incubator cooling during the last 12 days of the incubation cycle (exothermic eggs)

It is widely known that the setter is where the chick is mostly formed and that the temperature management, above all, is the most crucial.

A tight and precise temperature range is therefore a must in all incubators.

EMKA Hatchery Equipment manufactures equipment that is the most precise and uniform in the market today, and this is why !

Water is the single most efficient way of transferring excess heat in a closed incubator.

Air is only more efficient, but it is then in an open incubator environment.

The most critical parameter of artificial incubation is the embryo temperature, as this determines the metabolic rate and therefore the rate of embryonic development.

Traditional incubators use a linear radiator type of cooling with cooling water below the dew point.

This results in two states that EMKA has improved upon.

The first is that cooling with water that is below the dew point (< 25,5°C in an incubator) creates condensation.

No matter what some people claim, that condensation water will evaporate to some extent, resulting in sharp temperature variations known as temperature overshoots.

Traditional incubators are very good at compensating this, but that shouldn’t be the aim of the incubator.

The incubator design should be inherently to keep a stable temperature and not continuously fight to stabilize the machine.

The second is the linear cooling tube.

- Cold water enters the incubator at one end,

- picks up the excess heat from the air that has been heated by the embryos

- and ends up with warmer water in the cooling tubes at the other end.

This means that there is a cold side and a warm side in the incubator.

The fans do their best to mix the air as well as possible to cool the air.

The incubator is not stable and not really able to ensure an even temperature distribution, resulting in a wide temperature range in the incubator.

Temperature loggers show temperature variations ranging up to 10°F.

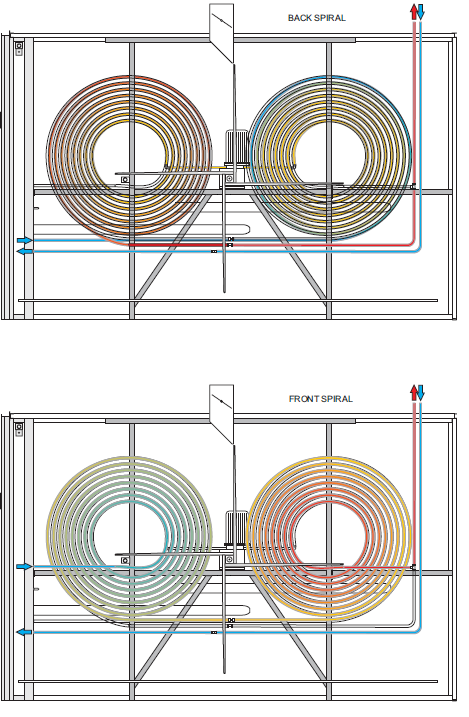

EMKA Hatchery Equipment uses its cooling tubes in a double cooling coil set-up. see picture:

As the water heats up by taking the embryos heat through a first coil, it is mirrored by a second coil that runs in the opposite direction.

The coils therefore compensate the hot and cold, producing that stable temperature we all look for throughout the incubator.

The front, back, top and bottom of the incubator therefore have the same temperature.

This results in the tightest temperature range and the best temperature control on the market today.

A 0.3 °F temperature variation in an EMKA incubator is the aim and is not uncommon.

EMKA Hatchery Equipment, stunning performance, every time !

Find out how EMKA can help you improve your chick quality with its Tightest Temperature Control.